Parure de lit Bio 2 personnes Herbier avec housse de couette et taies d'oreiller au meilleur prix | E.Leclerc

Promo Tissaia Parure Housse De Couette + 2 Taies D'oreiller Collection Florale chez E.Leclerc - iCatalogue.fr

Promo Parure Housse De Couette 200x200 Cm + 2 Taies D'oreiller 63x63 Cm chez E.Leclerc - iCatalogue.fr

Parure de lit - Housse de couette 100% Coton 47 fils Boheme Taille 240 x 260 cm au meilleur prix | E.Leclerc

Blanc Avenue Parure de lit 1 personne housse de couette + 1 TO 65x65 cm imprimé carreaux gris au meilleur prix | E.Leclerc

E.Leclerc Trie-Château - Le Blanc est un incontournable dans la vie de la maison ! Profitez de la qualité du linge de maison à prix E.Leclerc http://www.e-leclerc.com/trie-chateau/promotions/prospectus?OuvrirPaf=1&idPAF=18G050G | Facebook

Parure de lit 2 personnes Fauve avec housse de couette et taies d'oreiller au meilleur prix | E.Leclerc

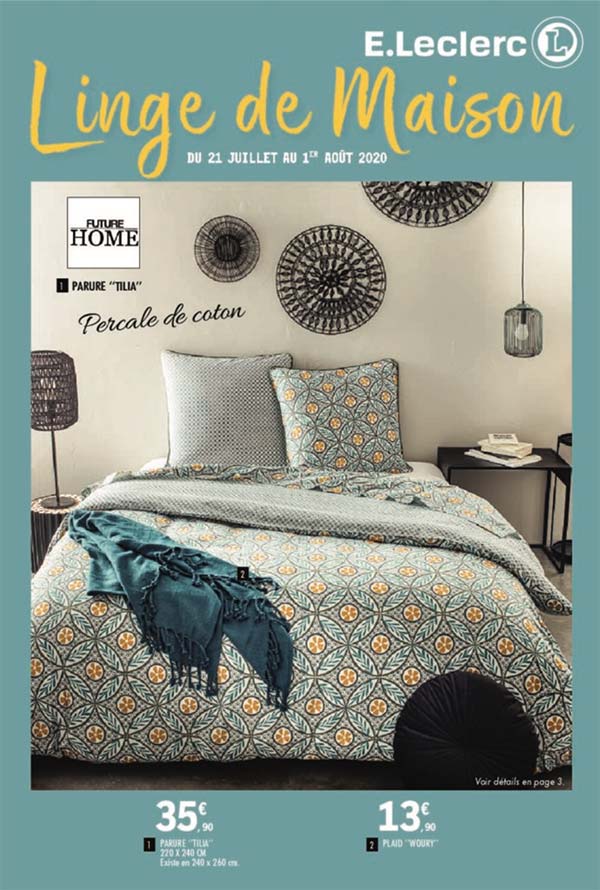

Promo E.Leclerc L EXPRESS DU 27 DÉCEMBRE 2022 AU 7 JANVIER 2023 COLLECTION FLORALE 100% coton 57 fils au cm² Bonheur TISSAIA PRIX DE LANCEMENT LA PARURE À PARTIR DE 28,95(4) € -50% 14€ ,47 PARURE H E.Leclerc