FS N8550-32C 32-Port 100Gb QSFP28 L3 Trident 3 Data Centre Managed Ethernet Switch, Bare-Metal Hardware - FS.com Europe

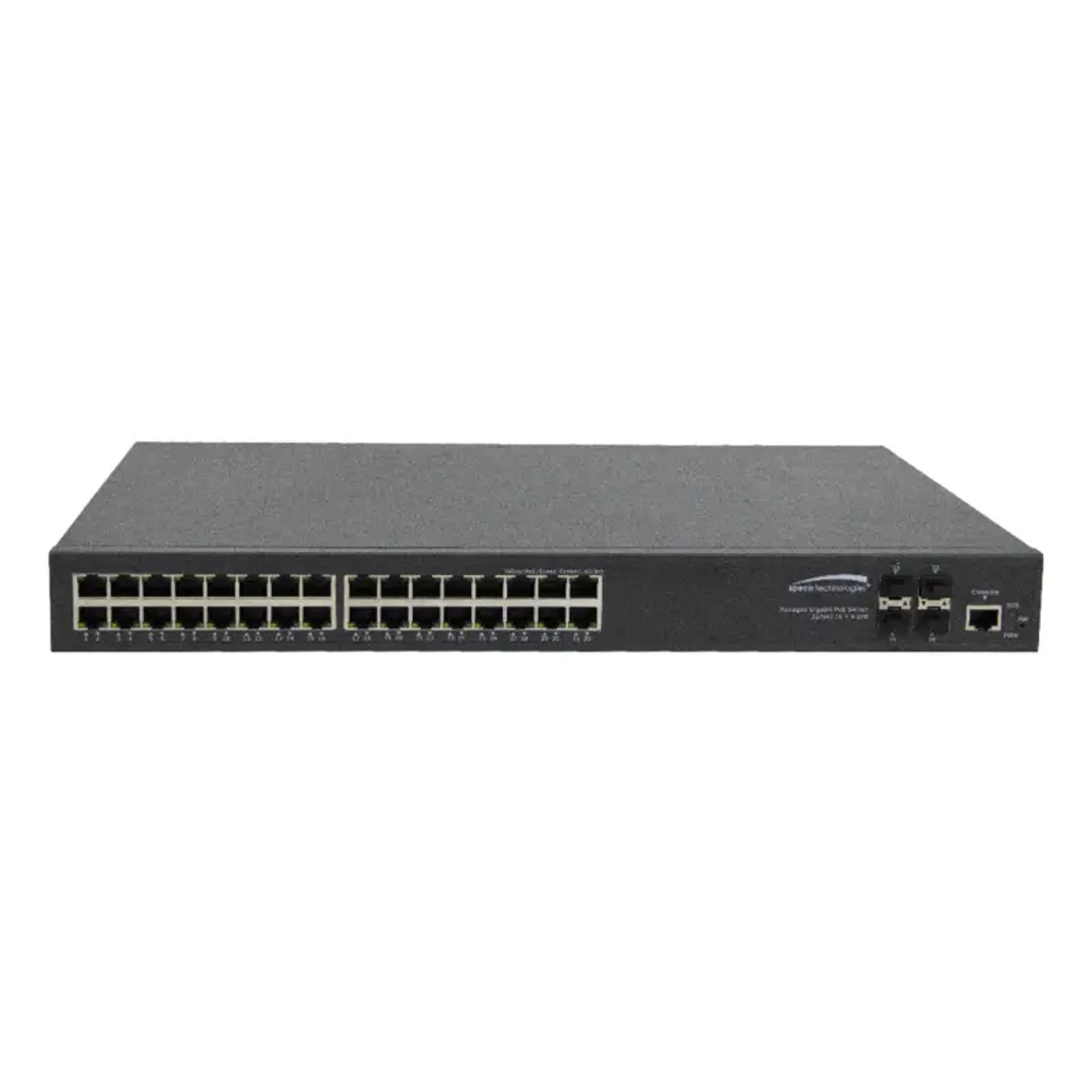

Managed Gigabit 32Port PoE Switch, 32 x 10/100/1000Mbps RJ45 + 4 x Gigabit SFP-Industrial Networking and Fiber Communication Experts

Kuwfi 32 Port Gigabit Managed Poe Switch High Power Ieee 802.3 At/af Protocol Suitable For Cctv Camera System/wireless Ap - Network Switches - AliExpress

32 Port Network Switch 24 Poe Port and 4 SFP and 4ge Uplink Port Poe Switch (TS2824F) - China 24 Ports Network Switch and Poe Power Supply price | Made-in-China.com